Construction Sealants at best price | Supex | India

Construction sealant definition & functions

Sealants are materials that prevent fluids and other substances from passing through surfaces and mechanical joints. Sealants also block air leakage, insects, dust, sound, and heat. There is a wide variety of sealants available in the market and their characteristics differ: they can be weak or strong, flexible or rigid, and temporary or permanent.

Sealants are typically used to close openings between surfaces, where other materials like concrete and mortar can’t be used. They serve three basic functions:

- Filling the gap between two or more components

- Providing a protective impermeable barrier, through which substances cannot pass

- Maintaining their sealing properties through their expected lifetime, under the service conditions and environments for which they are specified

To achieve these functions, it is necessary to match the most suitable sealant with the materials that will be joined.

Sealant Properties

When selecting a sealant, these are the most important properties to consider:

- Consistency: Sealants with high viscosity will not flow much from where they are applied, even on vertical joints. On the contrary, low viscosity sealants can even penetrate into a substrate, they are used in horizontal joints, and can be self-leveling.

- Hardness: This describes the ability of a sealant to resist deformation. Note that hardness is inversely proportional to flexibility, and as hardness increases the flexibility decreases.

- Weather Resistance: High performance sealants can withstand extreme temperature, sun and moisture, while remaining flexible and performing as expected.

- Durability: Sealants have an expected life cycle under ideal conditions. However, note that these conditions are not achieved in some applications, especially when sealants are misapplied or incompatible with the substrate.

- Movement: Movement tolerance is shown as a percentage of the joint width. This is determined by the ASTM C920 Standard Specification for Elastomeric Joint Sealants.

- Modulus of elasticity: Usually, low-modulus sealants have high movement capability and vice versa. Low-modulus sealants are used for delicate substrates, while high-modulus sealants are used in cases consisting of static or non-moving joints. There is a wide sealant variety in terms of modulus of elasticity, so applications may vary.

- Adhesion: The ASTM C794 Standard Test Method for Adhesion-in-Peel of Elastomeric Joint Sealants tests the adhesion of elastomeric sealants, which is a crucial factor when selecting them. Manufacturers provide adhesion data for sealants with various substrates.

- Staining: Sealant components may stain certain substrates, especially those that are porous, such as natural stone. Testing sealants before application is recommended, even when manufacturers claim their product is non-staining.

- VOC content: Volatile organic compounds are respiratory irritants that may be present in sealants. Manufacturers have developed sealants with low levels of VOC, but this does not apply for all sealants, and the best recommendation is always checking the VOC content.

- Cost: Sealant prices vary greatly, depending on their performance levels and applications. It is important to note that replacing failed sealants is usually more expensive than choosing the correct sealant from the beginning. Match sealants to the performance requirements to avoid future expenses.

Find out more about the construction sealants by signing up here.

Types of Construction Sealants

There are several types of construction sealants. They differ in cost and applications, based primarily on the performance properties mentioned above and the substrate properties.

| Sealant | Properties |

| Latex |

|

Acrylic sealant |

|

| Butyl sealant |

|

| Polysulfide sealant |

|

| Silicones |

|

Polyurethane sealant  |

|

MS polymer sealants |

|

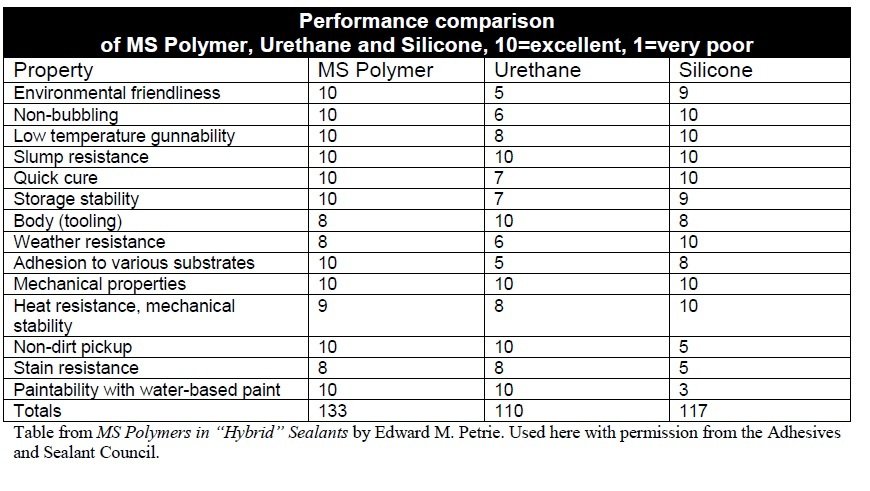

Why choose MS polymer sealant instead of Polyurethane,PU sealant?

The outstanding performance of MS polymer adhesive is recognised by industry professionals around the world.

MS polymer demonstrates numerous benefits over other products commonly found on the market today. From stronger bond strength to excellent workability, here are the advantages to using MS polymer over Polyurethane sealant:

Benefits of MS polymer

- Excellent UV, water,chemical, environment resistance

- Stronger final bond strength

- Isocyanate & solvent free

- Permanently elastic, even at low temperatures

- Good workability

- No shrinkage of cured product over time

- More responsive to increased moisture in substrates

MS Polymer sealant and adhesive

1. LM MS sealant : An elstomeric hybrid sealant on advanced MS polymer technology. It is a Low modulus sealant with high movement capability and excellent weathering characteristics. Sealing concrete joints, precast wall panels, expansion joint, control joint, FRC board etc. Sealing anodized aluminium, masonry, porcelian, coatedmetal, finished wood, epoxy and polyester panels, upvc, polystyrene and stainless steel.

2. All in one MS sealant : Medium modulus elastomeric hybrid sealant based on advanced MS polymer technology. Suitable for high strength sealing & bonding in construction, automotive, marine, industrial applications. It works on various substrates like plastic, metal , rubber, natural material ( wood, leather etc)

3. Auto body seam sealant: A high performance elastomeric hybrid sealant based on advanced MS polymer technology. I t has fast drying speed, good UV & temperature resistance. Ideal for making permanent elastic seals of high bonding strength, expecially interior exterior auto bodyseams & joints.

A high performance elastomeric hybrid sealant based on advanced MS polymer technology. I t has fast drying speed, good UV & temperature resistance. Ideal for making permanent elastic seals of high bonding strength, expecially interior exterior auto bodyseams & joints.

4.  All clear MS adhesive: a clear colour MS polymer sealant formulated for bonding & sealing applications for long term reliability. It will bond to form a durable, flexible, waterproof seal. Ideal for bonding plastics, metal, rubber, wood , leather,paperboard, concrete etc.

All clear MS adhesive: a clear colour MS polymer sealant formulated for bonding & sealing applications for long term reliability. It will bond to form a durable, flexible, waterproof seal. Ideal for bonding plastics, metal, rubber, wood , leather,paperboard, concrete etc.

5. High perfomance MS sealant: is a Hybrid Silyl Modified Polyether technology based high grip one component strong adhesive. It is suitable for direct bonding on a wide range of heavy construction materials without support and able to hold up to 13 kg weight. That is why support of the adhesive assembly is not necessary in general. It has high performance mechanical properties and combines high stiffness with very high bond strength. It is recommended for usage in sealing and bonding in building and construction industry.

6. Primerless auto glass sealant: mositure cured high modulus MS polymer sealant formulated for windscfreen bonding applications. It has high green strength & excellent resistance against weathering & temperature extremes. It is solvent free and not shrink after curing.

7. MS flooring adhesive: is based upon Hybrid Silyl Modified Polyether Technology. it is an odourless, one part flooring adhesive suitable to bond many types of parquet flooring to almost any sub-floor. it has a high bond strength between the wooden floor and the sub-floor but remains permanently flexible. it is an ideal product for indoor and outdoor bonding and sealing purposes.

For knowing more about MS polymer technology you can sign up here.

Kindly post your questions/ queries in the comment section or contact me at:

Bibhas Agarwal

anaghaengineers.in@gmail.com

Whatsapp: 91 9833892782

Call : 91 9699892782

www.anaghaengineers.in