Wastewater Treatment | Adhesive & Sealant manufacturers | Supex India

Industrial Adhesives Sealants used in wastewater treatment plants

An industry that consists of facilities and plants in large and small populated areas where wastewater treatment is needed.

- The wastewater treatment industry consists of plants whose goal is to provide waste water treatment services to the population. The average wastewater treatment plant employs 3-10 maintenance personnel responsible for the maintenance of pumps, containment areas, equipment and facilities associated with the treatment of wastewater.

- A water treatment plant size and planned capacity is determined by the population of the area in which it services. The quantity output is measured in gallons treated per day or per week. As the population of an area increases the larger a plant must be made or a new plant must be built.

- To make a current plant more reliable means that the life cycle of the plant can be extended and the mean average of water treated between breakdowns can increase.

Industry Statistics – Definition and Classification of Water Treatment Industry

- A plant that treats 20-35 million gallons per day ( a plant for a city of 40,000) will have 3-10 maintenance personnel and would be considered a medium size plant.

- A plant that treats 175 million gallons per day (a plant for a city of 1.5 million plus) can have 70-100 maintenance personnel, 10-30 electricians and up to 30 facilities and fleet maintenance personnel and would be considered a large plant.

A water treatment plant will employ approximately 10 maintenance personnel and or engineers/electricians to maintain and repair equipment.

Typical areas of concern in a water treatment plant involve the consideration of caustic materials, corrosion, mechanical abrasion and the containment of materials while in the treatment process.

Currently populations are growing faster and the demands on treatment plants are increasing. In response to this, new plants are being built and older plants are being retrofitted to increase their treatment capacity. The result is larger plants with more equipment and capacity

The most common maintenance functions are the repair and upkeep of pumps, concrete and transport systems on the facility (Conveyors, pipes, hoppers).

The industry has responded to this by looking for repair materials that will extend the life of their equipment and prevent common leaks, corrosion and loosening.

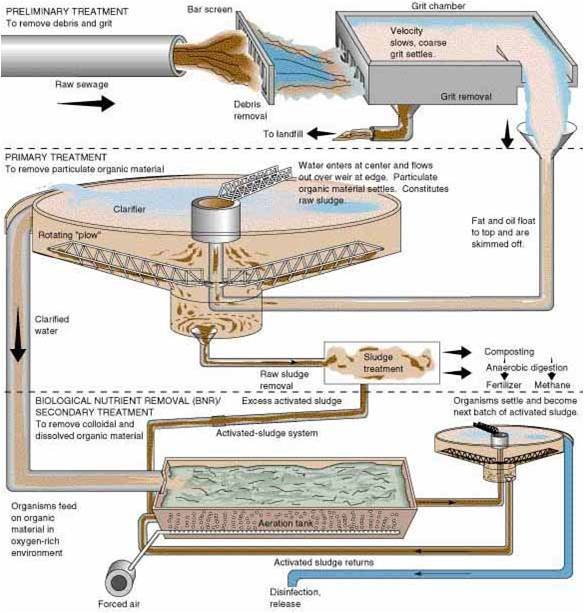

Wastewater treatment process

Description of Common Equipment in the sewage Treatment Industry

Conveyance System The Sewer Lines

This system consists of hundreds of miles of sewer pipe and drainage pipe that route the water from homes, businesses and streets to the wastewater treatment plant.

This entire system of pipes and man holes contains Supex applications

for Coating, corrosion prevention, Sealants and repair epoxies.

Pump Station

Gravity will carry the water from homes to the treatment plant. When slopes have to be overcome pumps in a pump station along the sewer lines boost the water and raise it over the slope.

The pumps at a pump station can range in size from a 2 inch discharge to an excess of 14 inches. These pumps are located in stations in areas where wastewater is collected and must be assisted via the pump in order to reach the treatment plant.

Bar Screen

This piece of equipment consists of bars that screen out trash and large contaminants from the water as it enters the treatment plant. The screen at left has captured a tire and removed it from the water before it entered the plant.

This piece of equipment consists of bars that screen out trash and large contaminants from the water as it enters the treatment plant. The screen at left has captured a tire and removed it from the water before it entered the plant.

Grit Chamber

These concrete chambers slow down the flow of water after it has passed through the bar screen. Organic material stays in suspension as the mixer turns the water but sand, rock glass, metal and other grit will settle out. The remaining water moves through the treatment process.

slow down the flow of water after it has passed through the bar screen. Organic material stays in suspension as the mixer turns the water but sand, rock glass, metal and other grit will settle out. The remaining water moves through the treatment process.

Screw/Auger Press

An auger in a chamber will mechanically press water from debris and grit that has been filtered from water entering the treatment plant.

Separated solids are taken to a landfill (shown in red) and the water (shown in blue) continues through the treatment plant.

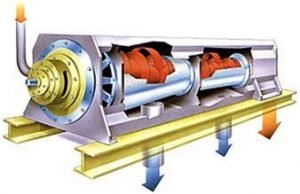

De-watering Centrifuge

Sludge (water and solid waste) enter the centrifuge and like a large washing machine on spin cycle the material is flung at high velocities against the side of the drum. The separated water (in blue) continues through the plant and the “cake” (de-watered material shown in red) is mixed with compost and/or fertilizer.

Sludge (water and solid waste) enter the centrifuge and like a large washing machine on spin cycle the material is flung at high velocities against the side of the drum. The separated water (in blue) continues through the plant and the “cake” (de-watered material shown in red) is mixed with compost and/or fertilizer.

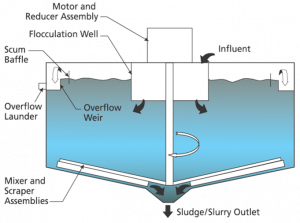

Clarifier

These cone shaped concrete chambers are common at all sized water treatment plants.

A scraper will remove the scum from the top of the water while

a urethane spatula will scrape

the heavier sludge from the bottom. The “cleaned” water moves up and to the outer

edges to continue through

the treatment plant.

Sludge Pumps

Each plant may contain up to

400 pumps of different sizes and configurations and for different purposes.

A sludge pump will pump water that is filled with solids (sludge) to the next step in the water treatment process.

Recurring maintenance issues

- Mechanical failures due to fastener & bearings loosening

- Corrosion of metal parts

- Erosin of pump casings

- Gasket failure

- replacement of worn out parts

Adhesives and sealants used

- Engineering adhesives : Threadlocker, threadsealants, bearing retainer, flange sealants

- Rebuild and repair metal epoxies: Steel putty, Titanium putty

- chemical resistant coatings

- Adhesive for general metal, plastic, rubber bonding

- anti seize chemicals

- maintenance sprays eg: rust loosener and lubricant

- silicone and PU sealants for sealing and bonding

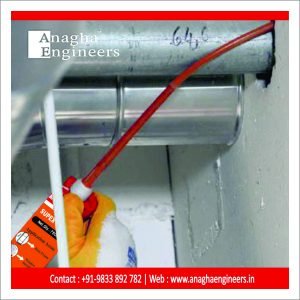

PU Sealant uses | How To Use PU Sealants | India

What is a PU Sealant

PU Sealant is a one-part, elastomer sealant based on urethane which cures at room temperature. It is mainly used in applications relating to assembling and sealing. For these applications, the product is referred to as adhesive sealant or polyurethane adhesive sealant. The main attractive features of PU sealant is its good resistance to impacts and vibration due to its elasticity (the product can be used to assemble materials with different coefficients of thermal expansion), and its impressive mechanical performance.when it comes to sealants, polyurethane is the most common choice next to silicone. The two types of sealants are both flexible allowing for up to 50% movement and they keep water and air out. However, they also have differences: polyurethane sealant is organic and silicone is inorganic.

Due to their organic nature, polyurethane sealants tend to be less durable than silicone. They often have a life span of 5 to 10 years whereas silicone can reach the double. However, this can also be seen in the price: polyurethane sealant is usually about a half the price of silicone.

Features and advantages

- one part mositure curing system- no mixing required

- Excellent tear and abrasion resistance. high flexibilty– can withstand high vibrations

- versatile adhesion compatibility with many substrates, such as stone, concrete, metal and wood.

- High gap filling capability-ability to be used in a broad range of joint sizes.

- Paintable

- good chemical resistance- can withstand harsh environment

Filling the Gap Between Rubber and Plastic

Polyurethane sealant is outstandingly able to withstand more loads than rubber because they are harder than rubber and yet more flexible than plastics. Their flexibility is accountable for their strength and remarkable ability to resist impact.Abrasion Resistance

Polyurethane is the best sealant for applications against severe wear regardless of low temperature. For some decades now, they have been the most used materials for environments that are highly abrasive owing to their super ability to resist abrasion. No other form of elastomers, metals, and plastics has a better abrasion resistance than urethane sealant. Their abrasion resistance ability is rated to be 10 times better than what other materials can provide.Oil and Chemical Resistance

Like their abrasion resistance ability, the properties of polyurethane materials are highly capable of resisting oil and chemicals. This enables them to maintain stability (with minimal swelling) in water or oil etc. If you are looking for elastomer materials to use in subsea, then polyurethanes should be your ideal choice.Affordable manufacturing process

Productions such as prototypes as well as one time products or one-off parts are often manufactured using pu sealant.Polyurethane Resilience

Resilience is generally a product of hardness. Polyurethanes are the perfect choice for elastomer applications that can absorb shock. They have a high vibration frequency or outstanding ability for quick recovery. Their remarkable resilience ensures polyurethanes are very tough materials.Uses of Polyurethane Sealant

PU Sealants Used for Sealing Purposes

Polyurethane sealants are among the most widely used technology for both new and renovation construction projects. Available in single and multi-component formulations, polyurethane sealants are mainly used in horizontal joints or non-sagging, vertical applications. In particular, these include:

- Isolation joints

- Roofing

- Foundation

- Gutters

- Expansion and control joints

PU Sealants Used for Bonding purposes

Polyurethane sealants with Shore A hardness of 45 and above are referred to as adhesive sealants. They have high surface adhesion and low flexibility. Especially in automotive industry used in the manufacture of vehicles, in the repair of auto glass, in the sealing of metal structures such as containers and trucks, in the manufacture and installation of air conditioning in HVAC systems, in order to reduce vibration and provide sealing in metal sheet joints.

Names commonly used in the market; Polyurethane adhesive sealant, extra strong polyurethane sealant, Premium polyurethane sealant, PU auto glass adhesive, PU metal adhesive, PU glass adhesive and PU marine adhesive.

Bus and coach applications

- floor bonding

- seam sealing

- structural bonding

- frp bonding

- bus a/c & roof sealing

- stretch panel bonding

- windscreen and rear screen bonding

- rain channel fitting

- window outer sealing

PU sealant is also used in the manufacturing of Elevators, railway coaches, white goods, HVAC systems, adhesive for metal to metal, bonding metal to metal, steel to steel adhesive, best construction adhesive for metal, adhesive bonding metal, bond metal, metal adhesive, metal to concrete adhesive, metal to metal bond, best adhesive for metals, best metal adhesive.

Types of 1K polyurethane sealant

A. Self levelling PU sealant

Boss PU SL – Boss Self levelling Polyurethane sealant Applications -Sealing of shrinking joints in concrete floors. -Sealing of floor joints. – All usual horizontal building, connection, expansion and dilatation joints . Excellent for sealing of joints in environments where fuel and oil contact occurs. · Hydraulic fluids, lubricants, oils – Fuels (petrol and gasoline): Resistant to splash and spillage contact.

B. Low modulus PU sealant

Boss PU LM – Low modulus PU sealant from Boss producs Accumetric silicones. Applications – All usual building joints with high movement. – Connection joints between window- and doorframes and walls. – Expansion joints between many different construction materials. – Joints with large movement.

C. Construction PU Sealant

Soudaflex FC Applications: – All sealing and bonding applications in the building industry – Structural bonding in vibrating constructions Boss PU 25D. Industrial metal bonding PU sealants

Used for bus body building, white goods, Elevators, Escalator, HVAC, Railway coaches Boss PU 25 Supex PU 25 PU 25 bonds well to a wide variety of substrates and is suitable for making permanent elastic seals of high adhesive strength. Suitable substrate materials include timber, metals, metal primers and paint coatings (two-component systems), ceramic materials and plastics. can be used for bonding or sealing lap seams on trucks, bus, trains, trailers, roofs vans,RV’s specialty vehicles and constructions panels Soudaflex 611

E. Auto Glass bonding

Windscreen bonding, glazing Rear screen bonding Window glass glazing in railway coaches, bus etc Silicone VS Polyurethane Sealant

When you use sealant, you effectively form a seal, which prevents the movement of fluids and liquids. Sealant is sometimes compared to caulking. The main difference between building caulking and sealing is the flexibility of the seal. Sealants tend to be made from much more flexible materials. This makes them useful for areas and joints where a degree of contraction or expansion may occur. They are not the same as adhesives, but it is possible to utilise sealants that have adhesive properties. Although these sealants have similarities, there are some significant differences.

Chemical difference between silicone and polyurethane sealant

One of the principal differences between silicone and polyurethane sealants is the chemical composition. Silicone is an inorganic substance, while polyurethane is organic. The primary difference between organic and inorganic substances is the presence of carbon. Organic compounds contain a carbon atom. In most cases, a hydrogen atom is also present. With an inorganic substance, it’s uncommon for either atom to be present. Polyurethane is a polymer, which comprises of a series of organic atoms connected by carbamate. Silicone is a unique material because it contains both inorganic and organic compounds. These synthetic polymers comprise silicon and oxygen atoms, which are joined using C-Si bonds. The makeup of the chain exposes the organic elements of the structure to external influences.

This is why silicone makes such a versatile sealant. Silicone is commonly used in construction and the development of paint and food products. The chemical makeup of both silicone and polyurethane sealant are important. This is because the composition affects the breakdown of the materials. When organic and inorganic substances are exposed to UV light from the sun, the way they react differs. Inorganic materials are less responsive to UV rays than organic chemicals. In the long-term, polyurethane, an organic material, will revert back to its natural state in response to UV exposure. This affects both the lifespan and versatility of polyurethane sealant.

UV resistance of Silicone & PU sealants

Organic chemicals change in response to UV exposure. While inorganic substances are much more stable. The main base polymer used in silicone sealant is a stable compound known as poly-dimethylsiloxane. When silicone is exposed to UV light, the presence of inorganic compounds will prevent deterioration and disintegration. The silica-oxygen (Si-O) bond found in silicone sealants is much more resistant to UV rays than the C-O bond present in polyurethane sealant. The outcome is that silicone sealants are inherently stable and more robust in terms of weatherproofing. It is possible to make polyurethane sealants more UV stable by adding chemicals that are designed to absorb UV light or increase UV resistance.

Lifespan of Silicone and Polyurethane Sealant

As you may have inferred from reading about the chemical composition and changeability of inorganic and organic compounds; silicone sealants last longer than polyurethane sealants.

Typically, a polyurethane sealant will produce effects that last between 5 and 10 years. While a silicone joint could last more than 20 years. The difference comes down to the fact that silicone sealants won’t break down as a result of UV exposure. Another consideration to factor in is temperature. Just as UV exposure can alter organic chemicals, changes in temperature can also affect the performance of sealants. If you have a joint, which is subjected to changes in temperature, this can result in contraction or expansion. In this case, silicone sealants are almost always the best choice, as they are more flexible.

Price difference between Silicone and Polyurethane Sealant

Cost is a factor when it comes to choosing which type of sealant to use. There are two main issues to consider when you’re weighing up the options of silicone and polyurethane sealants. Firstly, the cost of the material. Silicone is significantly more expensive than polyurethane. The initial outlay may be double if you opt for silicone. The second factor to think about is labour costs. If you plan to do the work yourself, choosing polyurethane may seem like an economical choice. However, keep in mind how much time you’ll have to devote to the cause over the coming years. If you’re going to pay somebody to do the work for you, consider:

- the cost of one course of silicone sealant

- compared to two, three, or even four rounds of polyurethane sealant.

In the long-term, silicone may represent better value for money even though the initial cost could be significantly higher.

Moving from one sealant to another

It is possible to swap polyurethane sealant for silicone sealant, but this can be an extensive job. This is due to the fact that it’s essential to ensure that all the previous sealant is removed before placing the new sealant. If there are traces of polyurethane remaining underneath a silicone seal, for example, this could cause the seal to disintegrate. If you do plan to replace polyurethane sealant with silicone sealant, it’s wise to seek expert advice to make sure that the job is done properly. The cost of removing or repairing a failed seal is usually much higher than the fee charged to replace polyurethane sealant with silicone sealant.

Which type of sealant is best for which job?

Generally speaking, silicone sealants are more versatile and flexible than polyurethane sealants and they work better in most environments. The inorganic composition means that silicone is resistant to UV rays, making it a better option than polyurethane sealant, which will eventually revert back to its natural form. Silicone is compatible with many different materials, including glass, metal and tile, but it doesn’t bond well to wood. Polyurethane is often a better option for wood, as it dries hard. This drying process means that it is possible to seal wood, but it does make the job more difficult. As the sealant hardens, it’s much more difficult to apply. Sealants are used widely in many industries.

Technical & Commercials

- You have an application – call us for technical advice, demo, samples

- Buying PU sealants online – Click this link

- Contact us

- 24 X 7 helpline: 9833892782

Paintable Acrylic Sealant for uPVC Door & Window

What type of Acrylic paintable sealant do you require?

Answer: Lowest cost, means the lowest cost of the sealant bottle.

Maybe the customer doesn't even know the quantity of sealant per bottle.

If cost is the criteria for purchasing then should it be the lowest cost of sealant bottle OR lowest cost of sealing per DOOR/ WINDOW?

The total cost of sealing per door/window includes:

- Quantity of sealant used per door

- the labor cost of sealant application

- repair cost in case it leaks within the warranty period

- cost of ‘loss of reputation’

- uPVC window sealant cost per ml/ gms

Hence we must choose the right window/door acrylic paintable sealant.

There are few popular options to be used as uPVC window/door gap filler sealant.

|

|

Advantages |

Disadvantages |

|

Silicone Sealant |

Flexibility Weather Resistance |

Inadequate adhesion with the surface Difficulty in finishing, aesthetics Higher cost |

|

Acrylic Sealant |

good adhesion Finishing easy, aesthetics Paintable Low cost |

Low flexibility not a high gap fill ability |

|

Low cost Paintable |

Cracks with time Rigid High application cost |

Acrylic Paintable Sealant -Key properties required

- Flexibility, high elongation – does not break under expansion and contraction

- High Weather and UV Resistance

- Good bonding with surface- long life

- Paintable

- Low Cost – product and application cost

- High gap-filling capability ( up to 6 mm)

- Anti-mold / antifungal

Acrylic paintable sealant in India

This is an ideal choice as uPVC Door & Window Sealant because of the following reasons;

- Excellent bonding with uPVC, concrete, Brick, Granite

- High gap-fill capacity

- Paintable

- UV & weather resistant

- Solvent-free, water-based formulation

- Cost – lower than Silicone sealant

Application method

- The surface must be free of dust, grime, and grease

- Apply a uniform bead of the sealant in the gap

- The sealant surface may be smoothed with a wet sponge or fingers

Additional Application areas

- HVAC duct sealing

- Gap Filler – for sealing of construction joints

- Expansion joint sealant between prefabricated building material

- Installation of Wood, PVC, Iron, Aluminium joinery. Paint sealant,

- Joints of all kinds of Building material

- Crack filler – Internal and External walls, joints, etc

Packing, shelf life

450 gms cartridge, 12 months from date of manufacture, store in a dry place at around 30 C.

NOTE: Not suitable for glass bonding. Recommend to test the product sample for any application before using it for mass production.

What is an acrylic sealant?

An acrylic sealant is a synthetic, water-based ingredient made from acrylic resins, used for caulking, jointing, and filling cracks and gaps in using the construction, HVAC, and other numerous applications. It is a popular sealant in India for uPVC door/window manufacturers too.

Acrylic sealant price and availability

Supex 500 is an acrylic sealant manufactured for India by Anagha Engineers, Navi Mumbai. With one phone call – 9833892782, you can get the material delivered at your site.

Acrylic vs silicone sealant

Acrylic or silicone sealants look very similar in texture and appearance. Sealants primary purpose is to fill gaps. Whether we use acrylic or silicone, depends on several factors.

1. What is an acrylic sealant and what is a silicone sealant

silicone and acrylic are similar in nature and in the cured state are rubbery, so can we distinguish between the two . Acrylic is matte and silicone glossy.

Acrylic sealant Silicone sealant

- applications of silicone and acrylic

Silicone has good elastic property and preferred in areas with joint movement. Anti fungal silicone is used in bathroom and kitchen Silicone is permanently elastic and therefore best suited for joints in the bathroom, kitchen and expansion joints.

– Expansion joints and connection joints in sanitary areas

– Sealing of expansion joints in the floor area and wall area

Acrylic is a plastoelastic sealant that offers some advantages over the silicone. It is paintable and can be used for cracks in masonry, which is unheard of with silicone. Acrylic is ideal for applications where no contact or little contact with water. The acrylic sealant keeps really well on plaster, walls, wood and plaster.

– Strain and connection joints in interior design

– Joints and connections to concrete, aerated concrete, plaster, masonry, wood, plasterboard, fiber cement, shutter boxes, window sills, etc.

- Advantages and disadvantages of acrylic and silicone

An important advantage is that you can paint over acrylic, has low/no odour.

Disadvantage is that it can not be used in damp places, otherwise you might get mold. Acrylic also draws dust and dirt as it is coarser in structure than silicone. Acrylic has a volume shrinkage during curing since.

With silicone disadvantage is the silicone is not paintable, low cost GP grade has volume shrinkage, strong odour. Advantage, however, is that silicone is permanently elastic silicone as a sealant.

- Application of acrylic and silicone

Acrylic and silicone are both dispensed with a caulking gun, battery operated gun or pneumatic gun. They are available in cartridges or sausages.

How long does it take for the acrylic sealant to harden?

Ambient humidity and temperature are the key factors. Water evaporates from the acrylic so it hardens more quickly in warm and dry conditions. Joint dimensions are also relevant. Hardening occurs from the outside in.

Which substrates can acrylic sealant be used on? Is a primer required?

Paintable Acrylic sealant is primarily used on absorbent, porous substrates. If the substrate is too damp, the acrylic may take longer to harden.

Primer is generally not required for application of acrylic sealant. . This sealant is not suitable for waterproofing.

How should an existing acrylic joint be reinforced or repaired?

Acrylic joints can be repaired using the same material. The adhesion between old and new acrylic is good. Any existing sealant must be clean and securely attached to the substrate

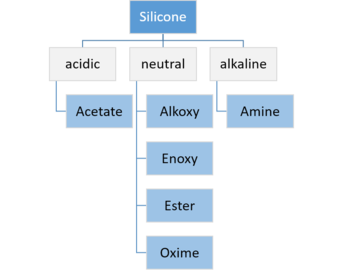

Silicone sealant selection & right price

Silicone Sealant is generally available in paste form. It cures (dries) after reacting with moisture in order to form a rubber-like flexible compound. Consequently, it also releases a by-product during this curing process. As a result of the by-product generated, Silicones are classified into two categories that are Neutral & Acetoxy silicones.

Silicone sealants are generally resistant to chemicals, moisture and weathering, making them suitable for indoor and outdoor applications. A silicone sealant can also be modified to match the needs of a specific application.

characteristics of RTV Silicone sealants

- Heat resistance: GP silicone sealant works upto 150C. High temperature silicone sealant. can withstand up to 315ºC (600ºF).

- Electric protection and insulation: when electric and electronic materials such as silver, brass and copper need sealing, one should choose for a RTV silicone which protects seals and insulates for example in the electronics industry.

- Resistance to microorganisms: silicone sealant waterproof are watertight and common as sealing solutions in humid environments such as swimming pools and industrial kitchens. For these applications the best choice is a sealant which resists mold and mildew as well as other harmful microorganisms.

- Chemical resistance: silicone sealant is generally resistant to some chemicals. Formula modification allows for example for acid and solvent resistance depending on the environment´s requirements.

Advantages of RTV sealants

- UV stability, long life

- Color stability.

- Chemical resistance

- Adhesion to variety of construction surfaces.

- Exceptional high movement accommodation.

- Extreme temperature resistance.

- High workability.

Classification: Silicone Sealant price & types

Silicones are classified with keeping in mind their curing systems

- Acidic cure, Acetoxy

- Neutral cure

- Alkaline cure

Acetoxy GP Silicone Sealant- low price

Most popular & thus used extensively due to lower price. One of the top selling product amongst silicones. Features including Acetoxy cure , low cost , low elongation, Resistant to sunlight making it undoubtedly suitable for general gap filling applications.Price is an important criteria for product selection thus making it the most popular above all. It Bonds to most substrates except PP, PTFE, LDPE, HDPE and low energy substrates.

Usess of low price acetoxy silicone sealant

These sealants ideally suited for sealing, glass, windows, shopfront, aluminium joints, showcases, bus body building and automobiles on the whole.

Furthermore, it is apt for building and construction joints , Glazing and connection joints, elastic joints in coldstore and container applications, Sealings in air condition systems last but not the least in General sealing for automotive applications

GP Silicone Silicone trend in India can be subgrouped into three categories based on brand value and price :

Firstly,High quality GP Silicones from reputed Brands like Dowsil, Wacker, Momentive, Mccoy, Boss . etc.

Firstly,High quality GP Silicones from reputed Brands like Dowsil, Wacker, Momentive, Mccoy, Boss . etc.

2. Secondly,Cheap priced imports from China : importers get low quality cheap products which is sold extensively through retail / Hardware Shops. Typically they sell at low price by reducing quantity of Sealant in the cartridge ( around 220 ml instead of 280 or 300 ml ).Likewise, they have lower shelf life too.

3. Lastly, Branded Silicones sealants which are admittedly in between the low cost sealants and high quality reputed branded GP sealants and as a result their prices are also in the middle bracket. Typical examples: Dr Fixit, Anabond , Smartcare ( Asian Paints) Resibond, Astral, Abro, Alstone etc.

Packing: 260 ml , 280 ml , 300 ml cartridge

Colours Available : Translucent, White, Black as well as Other special colours as per requirements.

Disadvantages of GP Silicone

- bonding with porous substrates is poor ,eg: concrete

- bonding with uPVC is poor

- strong odour

- releases acetic acid as by-product during curing, this acid is corrosive and corrodes metal surface. Automotive OEM generally dont use acetoxy silicones in the engine/transmission/ under the hood.

- it is not sensor safe

- durability and sustainability is lesser than neutral grade silicones

- shrinkage due to high solvent content

Neutral Cure Silicone Sealant

These are higher grade Silicone sealants particularly used for technical as well as critical applications.

Classification of Neutral cure silicones

1. Construction – Structural, Weather, Sanitary/kitchen, Neutral+ general purpose

1. Construction – Structural, Weather, Sanitary/kitchen, Neutral+ general purpose

2. Industrial– Gasketing/Flange sealing, Food grade approved, High temperature

2. Industrial– Gasketing/Flange sealing, Food grade approved, High temperature

3. Electronics :

Potting, Encapsulation, Electrically and Thermally conductive types

1. Silicone sealants for Construction:

A. Structural Silicone/ Glazing sealant

Silicone structural glazing is the use of a silicone sealant for the structural transfer of loads from the glass to its perimeter support system and retention of the glass in the opening.

Wind load and other impact loads on the façade are transferred from the glass or panel, through the structural silicone sealant and subsequently to the structure of the building. The silicone sealant must maintain not only its adhesive but also its cohesive strength on the facade for the reason of withstanding the wind loads and thermal stresses.

The one part structural silicone sealant packaging options allow for more flexibility of use by the installer, as the silicone can be conveniently used on building sites with minimal fuss.

B. Weather Silicone Sealant

These Sealants are used for typical construction applications.

Neutral Cure glazing silicone sealants are very popular due to its bonding capability with Glass and metals. Alongwith bonding abilities, excellent weathering ability makes it popular to be used against water / atmosphere admittance in metal structures and civil constructions.

Excellent adhesion properties especially on glass, laminated glass, coated aluminum, galvanized steel, concrete and masonry.

Alternatively, High tensile strength besides high elongation properties.

Uses of weather silicone:

- For weatherproofing sealing of nonstructural curtain wall joints,facade joints

- Weather sealing in metal, glass,stone,aluminum panel, and plastic

- All usual building, connection, expansion and dilatation joints

- Excellent for double glazing system applications.

- lastly, Weather sealing of expansion joints in the facade industry

Packings : 280 , 300 ml cartridge, 600 ml sausage

Colours: Black,White, Translucent as well as Grey

To sum up. Weather Silicone Trend in India can be differentiated in 3 categories

- Firstly, Most Popular and Highest selling weather silicone : Dowsil 789

- Secondly, Reputed brands including Wacker, Boss, Mccoy, Momentive etc

- Thirdly, Cheap Chinese imports.

However, this being a crititical application , contractors prefer to use reliable brands despite being a little costly.

C. General Purpose Neutral Cure Silicones

GP Neutral cure silicone sealant is a multipurpose while being a cost effective neutral cure silicone sealant.

Uses of GP Neutral plus Silicone sealants: It should be noted that GP Neutral silicones sealant will bond to make strong weatherproof seal on most common building material in the case of glass, concrete, aluminium, brick, steel, ceramic, plastic and most porus & non porous Substrates.

Features and Advantages – GP Neutral cure Silicone :

- Non-Corrosive

- Neutral cure/low odor

- Low modulus, Permanently flexible

- Excellent adhesion to vinyl, wood, steel, aluminum, glass and plastic

- VOC Compliant

- Sealing electrical equipment

- Waterproof/weatherproof

Packing: 280 , 300 ml cartridge .

Colours : Translucent, Black, White, Grey . Special colours are made as per request.

D. Anti Fungal, Bathroom/Kitchen Silicone

One of the most well-known applications of a silicone joint sealant is in your bathroom and kitchen. In recent years bathrooms and kitchens have become more luxurious. More and more money and time is spent to create a “wet” area that ticks all the boxes of the consumer’s needs, demands and requirements.

bathroom and kitchen. In recent years bathrooms and kitchens have become more luxurious. More and more money and time is spent to create a “wet” area that ticks all the boxes of the consumer’s needs, demands and requirements.

Classic sanitary materials, such as ceramics, enamel and glass are being replaced by materials such as natural stone, stainless steel and plastics such as polyester and PMMA . In order to ensure optimum adhesion and to achieve a durable and sustainable seal on these “new” materials, also “new” joint sealants are required.

Characteristics:

One component RTV (Room Temperature Vulcanising)

Excellent UV resistance

Can be applied to overhead or vertical joints

Excellent adhesion on porous and non-porous substrates

Anti-fungus properties

Mould resistant

2. Industrial

Gasketing/ Flange sealing

You name any 2 or 4 wheeler, truck, tractor, Stationery engines, Generators, construction equipments like  Tipper, Trailer, Payloader, Dumper etc – each one of them as a rule have been sealed using advanced silicone sealants . Typical Automotive Engine applications include

Tipper, Trailer, Payloader, Dumper etc – each one of them as a rule have been sealed using advanced silicone sealants . Typical Automotive Engine applications include

- Oil sump to engine block flange sealing

- Transmission cover sealing

- Cam Shaft cover sealing

- Engine Block to Head Flange sealing .There are various sealing & bonding applications accomplished using such sealants.

These sealants are also used extensively in Industrial manufacturing like heavy duty pumps, gear boxes,white goods,LEDs, Solar units, compressors. They also find usage for MRO applications in process plants, eg: paper,power, chemical, sugar, mines etc.

Typical properties of Industrial sealants namely are

- High tensile strength

- High movement capability , elongation

- Resistance to chemicals, fuel , engine oil, transmission oil.

- Easy removal from the surface while overhauling and applying new sealant.

- Non corrosive and sensor safe – typically neutral cure silicone is used.

- High temperature resistance , from 150 to 450 C

- lastly, Withstand internal pressure upto 10 Bars

High Temperature Silicone sealants

These Silicones have high operating temperature capability ranging as high as 450 C.

Apart from high operating temperature capability they are characteritized by :

- Excellent adhesion or bonding strength

- Flexibility

- Resistance to chemicals, fuels

Generally,it is used for high temperature Gasketing ( flange sealing) , sealing & also bonding in Ovens.

RTV Food Grade Silicone Sealant

Food manufacturing plants , pharma units , clean rooms without a doubt have very stringent norms to adhere too.

Any chemical used in the plant which directly or indirectly comes in contact with the End product has to be ‘FDA’ approved ,ie: in other words, it is safe even if the used chemical comes in direct contact with the end product manufactured . Eg: Medicine manufacturing unit, Horlicks manufacturing plant.

For reason of such norms, customer insist on food grade approved sealant.

These are regular sealants used for gap filling, flange sealing, general bonding and sealaing. However, these are manufactured in the same way such that it passes FDA strict norms for incidental food contact with the chemical.

Packing: 280 , 300 ml cartridge

Colours : White/ Clear Silicone Sealant

Is Silicone Sealant Waterproof?

Silicone is one of the most prominently used sealants to achieve a waterproof, protective joint . The flexible, rubbery sealant has high heat resistance and low toxicity, making an ideal sealant choice for plumbing pipes, aquariums, ships, and other metal fabrication projects that require a watertight seal.

Does silicone sealant stick to glass?

Silicone sealants are commonly used to bond surfaces such as plastic, metal, and glass together. Eg, aquariums are sealed with silicone. Windows sealed to frames with silicone adhesive since it is weather resistant.

How long should you leave silicone sealant to dry?

While some sealants may dry to the touch quickly, silicone sealant takes approximately 24 hours to fully cure; humidity levels in the home can slow or speed curing times. We recommend waiting at least 3 to 12 hours before exposing the fresh sealant to water.

How do you remove Silicone?

Stop leakages with Gasket Sealant | Supex India

Liquid gasket flange sealant

Gasket sealant also called Formed in place ( FIP) gaskets ensure 100% sealing of flanged joints and also reduce overall costs. This article explains :

Gasket sealant also called Formed in place ( FIP) gaskets ensure 100% sealing of flanged joints and also reduce overall costs. This article explains :- types of flange gaskets

- advantage of gasket sealant over traditional solid gaskets

- Why solid gaskets fail

- RTV Silicone gasket sealant

- advantages and llimitations

- Design considerations for optimum performance of RTV Silicone gasket sealant.

Fluid seals are divided into static & dynamic systems, depending on whether or not the

parts move in relationship to each other. flanges are classified as static systems although they move because of vibrations, temperature and or presuure changes, shock, impact, etc.

Types of flange gaskets

There are three types of flange gaskets:

- conventional compression gaskets of cork, paper, rubber, metal and other asbestos free materials:

- “Cured in place” liquid compression gaskets cure in seconds with ultraviolet light prior to assembly( CIP)

- ” Formed in place” liquid gaskets cured after the parts are assembled ( FIP)

- Create seals

- maintain seals

- remain impervious to fluid flow

- remain compatible with the machinery

Many factors influence gasket choice. FIP silicone gaskets are well suited for low pressure joints with large gap potential such as stamped metal cover plates ; FIP anaerobic gaskets seal high pressure joints when both surfaces are rigid. Cured in place gaskets are ideal for sealing joints which may be frequently serviced.

Formed in place gasket sealant

Advantages of FIP gaskets over pre-cut compression gaskets

Improved reliability

- seals all surface imperfections

- allows true ” metal to metal” designs

- reduce compression set and fastener loosening

- anaerobic gaskets can add to structural strength to assemblies

- unitizes assembly to improve torque transmission between bolted flanged joints

Reduced costs

- relaxed machining tolerances

- eliminate gasket

- reduce labour costs with automatic application

- eliminate bolt retorquing needed with conventional gaskets

- allow use of smaller fasteners and lighter flanges

Easier application

- single component materialsno mixing

- applied semi- or fully – automatic

- vertical and horizontal appplications possible

Easier service

Why traditional solid gaskets fail

Compression gaskets require an initial compressive load to deform the gasket into the irregularities of the flange surfaces. They therefore must carry the bolt load. The major causes of failure and nleakage of compression gaskets are:

- Compression set – over time, the gasket loses its elastic properties and becomes less resilent. The load on the gasket and relative motion causes a geeneral decrease in the thickness of gasket , with subsequent leakage.

- Flange bowing – The area where the joint is most likely to leak is at the center of the flange where the smallest compression is produced by the bolts. This is where the maximum bending occurs from the internal pressure.

- Extrusion– Gaskets can be squeezed out between flanges by a combination of low compression ( less than the minimum sealing stress) on the gasket and internal pressure of the system.

- Bolt hole distortion – High stresses are transferred to the gasket material under the bolt head causing the gasket to crack, tear, rupture or extrude.

RTV Silicone FIP gasket sealant

RTV Silicone materials cure by reacting with atmospheric moisture.

RTV Silicone materials cure by reacting with atmospheric moisture.

Silicone RTV gaskets are beads applied to the flange area of a component. Assembly should happen within 10 minutes. Silicone compounds flow to form gaskets that completely fill voids, surface imperfections, scratches and out of flat conditions, etc. They provide a smal out amount of ‘sqeeze out’ both on the inside and outside of the joint. The excess squeezed out past the edges of the flange forms a fillet acting as a secondary seal. RTV silicone materials contain no solvents. Conversion from liquid to solid is virtually 100%, eliminating all potential leak paths.

Benefits of FIP Silicone Gaskets over other materials

- Seal large gaps- RTV silicone materials seal large gaps upto 6 mm.

- Flex with flange movement – Silicones have high elongation properties upto 600%, permitting them to move in joints with high differential thermal expansion or flexible flanges.

- Relaxed surface finish- Silicone gasketing materials allow relaxation of surface finish and flatness tolerances. In some cases, large gap filling capabilities allow these materials to be used on ‘as cast’ surfaces.

- Inventory cost reduction- Silicones eliminate the need for large and costly gasket inventories.

- Temperature range – RTV Silicones have a temperature range between – 70 C to + 260 C with intermittent exposure to + 315 C.

- Adhesion- RTV Silicone materials adheres well to many surfaces.

Limitations of FIP Silicone gasket materials

- Chemical compatibility- RTV Silicones are limited to sealing oil, coolant and air. They have poor resistance to fuel and aromatic solvents.

- High pressure- Silicones are not well suited toheavily stressed or high pressure applications due to high elongation and low tensile and shear strength .

RTV gasket sealant – gasketing design considerations

Successful designs with RTV FIP gaskets use the following parameters.

Flange Design

The RTV Silicone joint should be a single plane sealing surface. In cases a single plane sealing surface does not exist ( such as oil pan arches or half rounds), avoid the use of RTV silicone or use a moulded rubber insert in the arch. The flange should have a minimum width of 15-20 mm. For stamppings and non structural components, stands offs are used witha height of 0.5 to 1.25 mm. If stand offs are not used or the component is a structural member, then retention grooves are used. The retention groove is usually stamped or cast into one flange and the other flange is flat. The cross sectional shape of the retention groove is a circular segment which runs the length of flange starting & stopping at each bolt hole. Typical dimesion of the flange- kindly contact us for the same.

Bolt Span

Surface cleanliness is critical to successful jont seals. RTV silicone gaskets seal by adhesion , not compression, so it is necessary to assemble joints before the rtv material skins over. Adhesion must be maintained as the flanges move for the life of the joint.

More about gasket sealant technology

- Where can the liquid gasket be used, some popular uses of gasket sealants.

- How to use or apply the gasket sealant

- Common mistakes to avoid while using a gasket maker.

- What is a gasket dressing compound. How to use the sealant where we cannot replace a solid gasket due to product design.

- How to disassemble assemblies sealed with liquid gasket sealer?

- How to reapply silicone gasket sealer

We will discuss these topics in our coming blogs. In the meanwhle you can contact us for any queries related to adhesive and sealant technolgy whatsoever.

FAQ on Polyurethane Foam Spray Sealant

What is a Polyurethane Foam spray ?

Polyurethane Foam spray is dispensed as a frothy liquid which expands and cures into a solid foam ( Like Thermocol) insulation and sealant.

Where can I apply Polyurethane foam spray sealant?

Insulating foam sealants are useful for sealing holes, gaps and cracks around your home where air leakage could occur. Some possible areas to consider sealing around include:

- Window and door gaps

- Baseboards and vents

- Sill plates, pipe and duct penetrations

- Sink plumbing, floor/wall junctions, around electrical boxes (not inside)

Can I use polyurethane foam spray sealant outside?

Yes, you can. Exterior uses could include the following:

- Where the siding meets the foundation

- Gas and electrical penetrations

- Garage ceiling and wall joints

- Around outdoor faucets and exterior vents

- Landscaping applications such as stone wall repair, pond/waterfall fillers and repair, as well as to secure landscape blocks.

Will polyurethane spray foam support weight?

Polyurethane Foam provide Structural Support. It is lightweight, which makes it a good choice in situations where the weight of concrete would further damage a structure.

How big a gap can polyurethane foam spray fill?

Is PU expanding foam a good insulator?

How do you use hand held PU foam spray?

- clean the surfaces thoroughly such that it is free of dust, dirt, grease,oil.

- Always wear safety glasses and gloves.

- Moisten the surface using water spray bottle.

- Shake the can vigorously, about 20 times

- Screw the straw onto the can.

- Turn the can upside down.

- Fill the joint for about 50%

- Cut the excess foam after it is cured, normally after 30- 60 minutes

How do you seal windows with foam?

What if the cured PU Foam is left uncovered?

As PU Foam is not Ultra Violet Resistant, the color of uncovered PU Foam will turn to dark yellow from light yellow within a few days. In the long run the foam will disintegrate.

What material should we use to cover PU Foam spray sealant after application to protect it from UV. Rays?

PU Foam can be covered with plaster, plaster of Paris, polysulphide (in case of expansion joints) or acrylic elastomeric paints in some cases. Where finishing is not very important, paint can be applied directly.

How cost effective is PU Foam compared to any other materials used in similar kind of applications?

750 ml. dispenser gives coverage of at least 35 liters = 35000 cc., considering 10% handling loss than coverage is = 32000 cc., with reduction

On which surfaces can PU Foam spray be applied?

PU Foam can be applied on various surfaces such as wood, metal, concrete, brick, plaster, (except polyethylene, polypropylene, silicone and Teflon)

Is pu foam spray insulation waterproof?

PU Foam has a closed cell structure, which gives complete water protection however it cannot be used for waterproofing, especially where the hydrostatic pressure is very high.

Can PU Foam spray be used to fill wall cracks?

PU Foam may also be used to fill small cracks. For this purpose it is necessary to use the added reduction needles.

Can PU Foam be used for expansion joints? If yes, than what should be used to cover PU Foam?

Foam sealant can be used as a backup material in expansion joints and can be covered with Polysulfide/ PU sealant.

Is PU Foam toxic? Stability / Tack free time?

It is non-toxic as well as CFC free. Tack free after approx.10 min. can be cut after approx.30 min. Cured within 2 hours. Stable within 4 to 6 hours.

Is any different color or packing of PU Foam available?

B3 type PU Foam spray sealant comes in only one color i.e. light yellow. The cured foam can be painted according to customers need. There is only one type of packaging 750ml. dispenser can (Used with dispenser gun/plastic adaptor)

Is PU foam a barrier to insects and rodents ? Will mice eat expanding foam?

Regular Pu foam spray do not contain chemical rodent deterrents or rodenticides.

Mice can and will chew right through the regular expanding foam, but there are formulas that stop insects and rodents.

Mice can and will chew right through the regular expanding foam, but there are formulas that stop insects and rodents.

Such special grade PU foam, Eg; Supex 100 PUF help prevent insects and rodents from entering structures through voids, cracks and crevices.

Is it necessary to moisten the surface before using foam?

We recommend moistening because the system needs water to cure. Other benefits one will get: i. Better cell structure ii. Better adhesion iii. Faster curing iv. Better foam quality

Is puf foam resistant to water?

Cured foam provides a barrier to moisture. However, over time, small quantities (depending of skin is on the foam) of water vapor will migrate through the foam. If the skin stays on the foam, the weight will only increase by 5%. If the skin is cut away, the weight can increase upto 150%. In that case foam is not water resistant. The water vapour permeability depends on the density and the cell structure of the foam. If you got more open cell structure or a lower density the permeability will

How much does PU foam spray sealant expand?

The expansion is different for gun and hand-held foam. i. Hand-held foam will expand by 150-200% which means that you only have to fill the joint by 40-50%. ii. Gun foam will only expand by 50-100%, so you have to fill the joint by at least 50%. The expansion depends on the temperature of the ambience, temperature of the can and the humidity.

How should I store an opened can of gun foam spray?

The best thing you can do is leave the can on the gun. If you do not leave the can on the gun, clean the valve and the gun with Gun & Foam cleaner. We recommend to empty the can in the next weeks.

Is there a negative effect on the puf foam if the can is not shaken thoroughly prior to use?

Polyurethane foam consists of a prepolymer and a propellant gas, which form two layers during storage. The can must be shaken vigorously before use to create a homogeneous mixture. Insufficient shaking will result in poor foam properties such as a coarse cell structure and reduced foam volumes.

How much must the cans be shaken to ensure a homogeneous mix of the two constituents?

A canister should be shaken 15 to 20 times.

Does the canister need to be shaken again during use?

It is recommended to shake the can occasionally during use, and especially after interruptions, to avoid re-separation of the propellant & prepolymer.

How does the puf foam get the right amount of moisture?

Fresh foam absorbs moisture from its surroundings. In particularly dry environments it makes sense to wet the surfaces to be joined. But standing water droplets are to be avoided, as in this case the water would actually become a barrier to proper adhesion.

What happens when there is insufficient moisture on the surfaces or in the surrounding environment and no water has been sprayed onto the foam?

A lack of moisture leads to inefficient curing of the foam and, depending on the amount of foam applied, may lead to foam compression – even months later.

Is there any way to accelerate the curing process?

Yes, wetting; ideally from a spray gun. This will help to speed up the hardening process.

Is cured foam subject to ageing?

Cured foam does not age. There has never been a case during the thirty years that polyurethane foam has been in use that any failure has occurred through ageing.

Can gaps between polystyrene insulation panels be filled with one – component polyurethane?

Yes, one-component polyurethane foam can be freely used for such applications. It is free from solvents and does not attack polystyrene.

Is it OK to leave half-empty canisters attached to applicator guns?

Yes; in fact we recommend leaving a partially-full container attached to the gun. To store the gun and canister safely, the security screw should be tightened to secure the trigger.

Is it necessary to remove excess foam from the adapter, or can I simply insert the next canister?

Though the adapters are constructed from a non-stick material, it is advisable to remove any excess foam straight away with gun cleaning fluid: well-maintained tools last longer.

How long can a partially used container be left attached to a gun?

If the trigger has been completely secured with the security screw, a canister can be stored attached to the gun for a period of one to two weeks.

Why should we allow a minimum gap of 10 mm along the perimeter of a window and not less?

The gap of 10 mm.all along the perimeter of the window, allows the PU foam to spread smoothly through the surface of the wall, provides sufficient space for PU Foam to expand. The amount of PU Foam in the 10 mm gap is sufficient to provide the required strength and binding force between the wall and the window.

Is Polyurethane Foam spray fireproof?

B3 Grade is non FR type product while B1 grade is FR type PU foam

Is any training required for the application of PU Foam?

Application of PU Foam is very easy and does not require any special skill. However for the first time users training is recommended. Training will be given by the sales staff and/or by the dealer.

What precautions should be taken while applying PU Foam?

- Contact with foam should be avoided from body parts and clothes. In case the foam sticks to any part of the body or clothes, wash the affected area with PG2 PU Foam Cleaner

- The nozzle should be kept away from the body while

- The can should be kept in the Inverted position while

- Cured foam has to be removed mechanically

What is the purpose of Remover? Can any other material be used?

Remover is used to clean the dispenser gun and the needles. The Remover can be mounted on the dispenser gun, thus cleaning the dispenser gun more effectively. By using any other material the chances of damaging the gun increase.

How to clean/remove PU foam ?

If wet or uncured PU foam gets on skin, quickly and carefully wipe it off using a cloth without spreading the foam around then remove residual wet foam using acetone or fingernail polish remover (with acetone), or a polyglycol-based skin cleanser. Then wash with soap and plenty of water.

How do you remove cured expanding foam ?

- If the foam has not yet fully hardened, wipe off as much as possible with a cloth or paper towel.

- Blot the remaining foam with some acetone nail polish remover.

- Continue blotting the foam with the acetone until it is removed.

How easily can a window mounted with PU Foam be removed?

Window mounted with PU Foam can be removed easily by slicing through the foam, but removal of the window by force is near to impossible.

Does the foam develop and exert pressure during expansion and curing?

Yes, the foam exerts a pressure during expansion and through hardening. It is therefore advisable to fill gaps and cavities by no more than one third.

What should I do with excess foam such as that round doors and windows?

Cured excess foam can be cut away with a knife, saw or any similar implement.

Who are the Pu foam spray can manufacturers in India?

No one. As of April 2020 no one manufactues PU foam spray in can in India. High quality products are imported from Europe and the USA. Others from China.

Where is Expanding Polyurethane,PU, insulating gap fill foam available in Mumbai ?

Anagha Engineers makes PU foam spray available in mumbai and across India. Contact : +91 9833892782 for best deals.

PU Foam Spray Sealant Applications

Anagha Engineers specialises in top-class pu foam spray sealant. Pu spray sealant can find application in the case of Construction/ industrial demand and also within and around your homes. So we thought, why not list out some of the ways you can use it around the house? So this article will now list out some of the ways to apply PU foam sealant that you may have never thought.

Pest Control with PU Foam spray Sealant

We offer to you a simple innovative solution -Supex PUF. The advantage of using PU Foam sealant over putty and cement is that this product is formulated to have self-expanding properties. This expanded polyurethane effectively shapes itself like the dimensions of the hole or crack. Therefore, this eliminated even the smallest of gaps for pests to enter. Use Supex PU Foam for the best results.

Insulating electric boxes with insulating foam spray sealant

Most electrical boxes in India are highly unsafe. Why? Because there is rarely any insulation around it. But what can you do about it? Add some padding behind it using the expanding PU foam. Please use a fire-retardent PU foam spray sealant for this use, however. In Solar projects It is mandatory to seal cable penetrations with Pu foam .

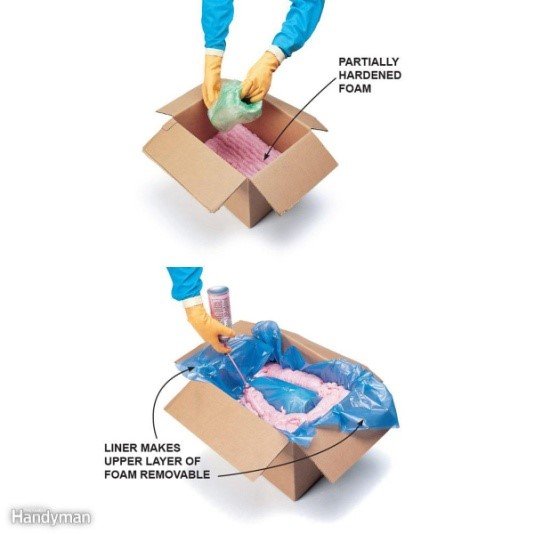

Securing fragile compenents in a Box for transportation with ga filling PUF sealant

We previously wrote an article about how we solved a fragile box being transported from getting damaged due to the lack of innovation. Check it out here. It is always best when you are not dependant on them to get across your shipment in one piece. But where does PU foam spray sealant fit in the picture? It’s simple, simple encase your material using the expanding properties of the foam!

First, line the box with plastic and fill it up to a third with the foam. Wait for some time so that the foam begins to stiffen just enough to support the material for transport. Line it again with plastic and then set the content inside the box carefully. Use on more plastic layer to cover the material. This allows the foam to separate into two pieces so that you do not face difficulty in removing your content. Remember, you do not need to fill more expansion PU foam spray on the top of the material. This product is expanding and will suitably take care of the content from careless dropping, carrying and transport.

QuickFixing your showerhead wth PUF sealant

The daily shower is the best ritual to freshen yourself up, any time of the day. But a wobbly showerhead can turn this ritual into a slightly annoying one. But here, we show you how to use a sealant to fix up this small problem.

All you have to do is clean the surface of the shower arm and then apply a little PU foam spray sealant around it. Wait for it to cure. Now this shower arm will not move anywhere. Carve off any excess polyurethane foam sealant that may develop after the expansion. Now slide the cover plate to the wall. It’s as simple as that!

This same trick can also be employed to fix up wobbly pipes around your homes.

Sealing Split AC Core cut holes with PU foam spray sealant

Builders nowadays make core cut holes for cable,pipes of split ac inside room to be connected with compresssor machine placed outside. However, the challenge is to seal the core cut holes through with the cables/pipes pass through.

As usual the traditional methods include stuffing solid thermocol, cement with mortar, caulking sealants( without cant fill such high gaps).

Sealing such holes with Pu foam spray sealant is gaining popularity with reputed developers. As this technique becomes popular, regular mechanics will aslo make this can a part of their tool kit.

Sealing Isolation/ Transition Joints with Polurethane foam – between beam and aac blocks.

PU FOAM SEALAN T – 1 component PU, packed in 750 ml can. Applied using a gun.

When extruded to fill the gaps/ cracks formed, Supex 100 Gun grade PU foam spray sealant expands to fill the gap effectively and seal the joint. Initially in liquid form, the expansion foam sealant cures upon expansion into a flexible material which can compress and decompress like foam.

The property to expand and contract is a highly desirable one. The joints can now offer a higher coefficient of linear expansion than that is shown by the rigid mortar technique. This, in turn, further reduces the probability of Beam- wall joint to crack. Another desirable property of the polyurethane foam sealant is that it also provides acoustical, thermal insulation.

Depending upon the requirements of the construction to be made, Supex 100 PU Foam is available in FR and non-FR variant

Few More applications of Pu foam spray sealant

- insulation of chiller pipes in HVAC system

- Sealing of all Openings in Roof construction, expecially metal roof

- Fire & Smoke Retardent sealant between wall, Floor and Ceilings

- Filling free spaces, cracks, gaps, pipe peneratations

- Back up material to Expansion joints

- Model making, design patterns etc

Limitations

- This product is extremely flammable when dispensing.

- it is not UV resistant, so avoid direct sunlight exposure. Else cover the cured foam with acrylic/silicone sealant, paint etc.

- not meant for bulk insulation like coldrooms, serves well as repair agent to fill gaps/cracks.

- Clean oil, dust and grease off surfaces to be foamed.

- Make sure to cover surrounding surfaces.