RTV Silicone Sealant FAQs | Supex India

What is RTV silicone sealant

RTV , Room Temperature Vulcanizing , Silicone sealant is a sealant in viscous liquid or paste form which cures into a flexible rubbery solid material when exposed to atmosphere. It reacts with the moisture from environment , cures and releases a bye product . Silicones are classified based on the type of be product released.

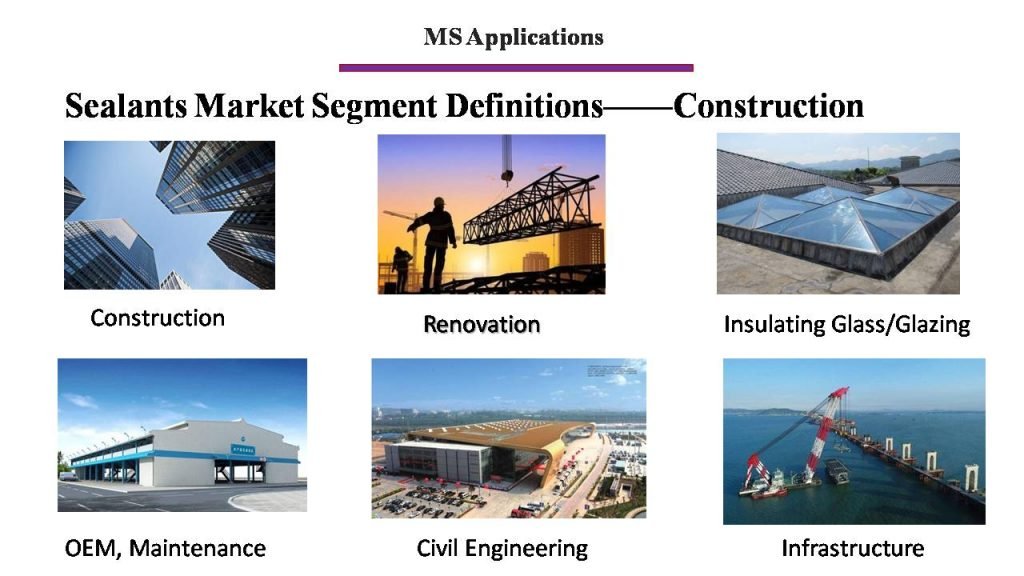

Silicone Sealant applications

Uses of RTV Silicone sealants. Silicone sealant is a very versatile product and widely used for a variety of applications.

NSF Certified Silicone Sealants, are the ideal rtv sealant to use in the manufacture, installation, maintenance, and repair of foodservice equipment, or applications where food contact may occur.

- pharma companies, clean rooms

- Foodservice appliance manufacture and repair

- Residential, Commercial, and Industrial refrigeration units

- Other applications where contact food may occur such as food display cases, transportation devices, etc

High Temperature RTV Silicone sealant are specially formulated for high temperature performance.

- Sealing and encapsulating heating elements

- Industrial seals

- High-temperature ductwork

- Sealing stove and furnace vent pipes

- Oven and wood stove window seals

- Industrial ovens

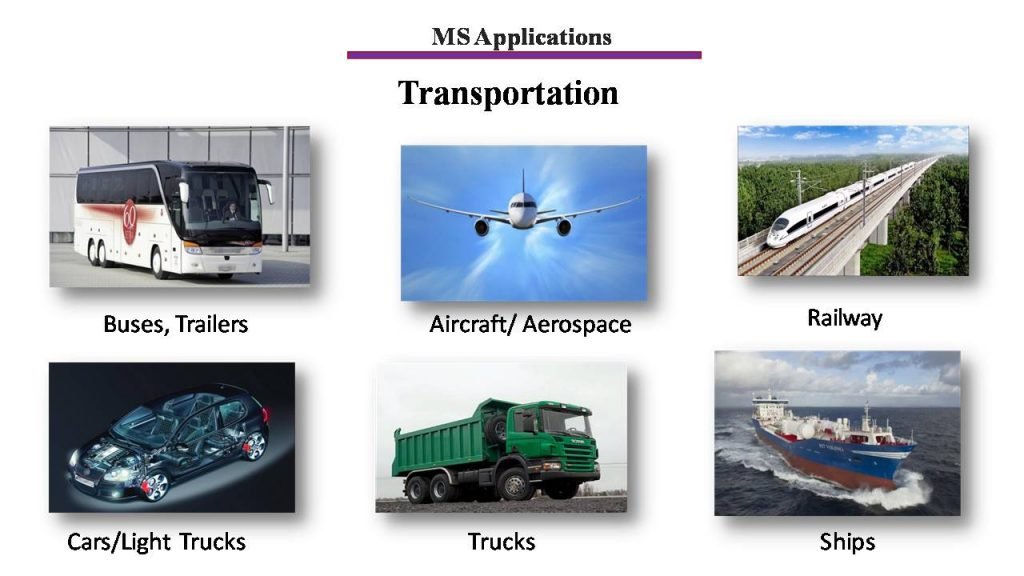

- automotive silicone sealant, automotive silicone adhesive, auto silicone adhesive, silicone sealant for cars, automotive rtv

Antifungal/mild dew silicone sealants are specially formulated to inhibit the growth and spread of mildew – a type of mold characterized by a dark colour & offensive musty odour. Mildew can pose a host of health concerns, and so inhibiting its growth is important.

-

- Tub, tile, sinks, and counters

- Shower stalls

- Floor drains

General silicone sealant uses:

- HVAC/R applications such as penetrations through the exterior of a construct

- Electrical applications such as service entrances

- Roofing applications

- Plumbing applications

- RV, trailer, and speciality vehicle manufacture and repair

Flange sealing/ Gasketing: replacing solid gasket in Engine, transmission, heavy-duty gear box, turbines, pumps, casings & etc

Advantages of Silicone sealant and adhesives

Advantages: First, because of its molecular structure and high bond energy, silicone has excellent ageing characteristics and is resistant to ultraviolet light and weathering. This gives silicone a longer effective lifespan than organic materials,such as EPDM, polyurethane, polysulfide and butyl, which are prone to degradation from UV light.

Types of Silicone Sealants

Silicones are classified with keeping in mind their curing systems

- Acetc acid cure,Acetoxy

- Neutral cure

- Alkaline cure

Acetoxy Silicone sealant

Most popular & thus used extensively due to lower costs. One of the top selling product amongst silicones. Features including Acetoxy cure , low cost , low elongation, Resistant to sunlight making it undoubtedly suitable for general gap filling applications.

GP Silicone sealant – Why is it so popular in India

GP, General Purpose Silicone sealant is a very popular silicone used in India for sundry applications. Though it may not be the right/best sealant yet its popularity leads to the question why.

- low price – DIY Silicone is sold from local Hardware shops. The ‘low cost types’ are sold in 240, 260 gms cartridge, actual sealant is approx 170-180 ml per cartridge. The end customer is happy to get one tube( size of cartridge looks the same as 280 ml ) at low price and the manufacturer/importer is happy since the price/ ml is still not less. Also sometimes the ‘B’ , ‘C’ grade silicones are imported at very less cost too.

- availability: it is widely and easily available unlike other sealants which is sold through institutional channels and a DIY customer doesnt have access to it.

- Awareness: local plumbers/waterproofing agencies/ electrician/ end customer are satisfied having used a sealant instead of putty or traditional sealing material. As the market matures the consumer would ask for suitability and quantity of sealant. Manufacturers would educate and differentiate their products from the commodity.

Disadvantages of using GP Silicone sealant

- bonding with porous substrates is poor ,eg: concrete

- bonding with uPVC is poor

- strong odour

- releases acetic acid as by-product during curing, this acid is corrosive and corrodes metal surface. Automotive OEM generally dont use acetoxy silicones in the engine/transmission/ under the hood.

- it is not sensor safe

- durability and sustainability is lesser than neutral grade silicones

- shrinkage due to high solvent content

Neutral Cure Silicone Sealant

Higher grade Silicone sealants particularly used for technical as well as critical applications.

Classification of Neutral cure silicones

- Construction – Structural, Weather, Sanitary/kitchen, Neutral+ general purpose

- Industrial- Gasketing/Flange sealing, Food grade approved, High temperature

- Electronics – Potting, Encapsulation, Electrically and Thermally conductive types

How to apply silicone

Sealants

- Clean and prepare the surface by removing old sealant dirt, and other debris to ensure a strong adhesion between the sealant and the surface.

- Apply masking tape at the edges ( beyond the joint to be sealed) – this will ensure sealant remains inside the joint , also edges dont get smeared with sealant – better aesthetics

- Cut the tip off the cartridge and screw on the removable nozzle and cut tip to your desired bead size. Insert cartridge into standard caulking gun.

- Hold at a 45° angle and apply silicone sealant ahead of nozzle to achieve a smooth seal

- Complete tooling within 5 minutes using your finger or a damp paper towel. Use a dry paper towel to remove excess material.

- Sealant normally “skins over” in 5 minutes, dries to touch in 1 hour, and cures & bonds in 24 hours. Allow 7 day cure time to reach maximum strength.If you require more than one tube for your project – you can screw the nozzle from the previous tube onto the new cartridge in order to keep your bead size consistent.

- If you have sealant remaining in the tube, seal the tip with masking tape or grease to prevent air exposure

- Wipe hands with a dry cloth, and then wash with soap and water.

- for repetitve work you can use battery operated sealant gun for site work , pneumatic gun for production work. Sealant consumption/wastage is reduced, worker efficiency improves due quick application with minimum physical effort.

FAQs RTV Silicone Sealant

Is rtv silicone paintable?

Silicone sealants are not paintable. For a paintable solution, we recommend our acrylic sealant, Supex 500, or ms sealant, Supex Bond All.

What colours do rtv silicone adhesives come in?

They are available in Clear, White, Black, and grey. Popularly they are called clear rtv silicone, white silicone sealant. Special grades are available in brown ( RAL 8017, 8007), Grey ( RAL 7047), ivory, Brilliant white etc. for bulk quantities we can make in the colour of your choice.

Do I need to use different rtv silicone for different jobs?

Yes. silicone sealant differ in their formulations and their intended use. Properties like adhesion, flexibility, elasticity, and durability vary substantially from product to product so it is important to select the right product for each job.

If you need to know the best sealant to use for your application, contact us. We will be happy to help you select the best product for your application.

Do I need to prepare the surface material before applying rtv silicone adhesive sealant?

It is recommended that you adequately prepare the surface(s) to be sealaed so as to ensure a tight, strong seal. You should prepare the surfaces within 24 hours of application of the product.

- For metals, glass, plastics, and other similar materials prepare the surface by applying a solvent such as mineral spirits. Make sure to wipe the surface dry with a clean cloth. When using solvents, make sure the area is well-ventilated. Make sure to follow any and all safety precautions.

- For porous surfaces, use a sandpaper or wire brush where needed in order to ensure a clean surface.

Do not use silicone on galvanized surfaces. Do not use in areas that will be continually submerged in water. Do not clean with a detergent or soap & water as silicone will not adhere well to surfaces where soap residue and/or soap scum is present.

Can I apply new rtv silicone over, or alongside old silicone sealant?

It is recommended that any old silicone sealant is removed. While new, freshly applied rtv silicone can be applied & will bond to old silicone – the bond isn’t as strong as if it were applied to a clean surface.

What do the terms “Tooling” and “Tooling Time” mean?

- Tooling refers to ‘working’ the caulk, often times to smooth or otherwise manipulate the caulk.

- Tooling Time refers to the amount of time you have to “Tool” (or work) the silicone before it begins to skin over

What is the tooling time for silicone sealant?

Normally rtv’ adhesives begins to skin over in 5 minutes, so all tooling should be completed within that time frame.

What does the term “Skinning Over” mean?

Skinning over means that the product has begun to cure and has developed a firm skin formation on the surface.

How do I store silicone sealant?

- Remove the screw on nozzle, and make sure any air is removed by pushing the sealant to the tip of the cartridge before replacing the screw on nozzle.

- Replace the removable tip.

- Store in a cool, dry environment.

Does silicone sealant go bad?

Anagha Engineers stands behind a one year shelf life guarantee of our silicone sealant adhesive products, from date of manufacture. This is tracked by batch numbers, which indicate the date of production.

You can always test the sealant before starting a project by running a small bead of it on a scrap piece of wood, cardboard, etc. If after approximately 15-20 minutes the product has not formed a “skin”, the product is most likely expired and will not fully cure.

If the silicone adhesive has hardened (cured) in the tube, it can not be used and has most likely passed its shelf-life. If you have reason to believe the product has not passed its shelf life, return it to the place of purchase or contact Anagha Engineers directly.

Once I have applied the silicone, how long do I need to wait for it to cure?

Typically silicone sealants will cure in 24 hours. This cure time could vary depending on environmental factors – primarily the moisture in the air. Since this is a moisture curing silicone sealant, it relies on the moisture in the air to cure.

How much will a single tube of silicone sealant cover?

Available in 260,280,300 and 600 ml packing. The yield from these cartridges varies from application to application, based on the joint depth & width and bead size. You can utilize our sealant calculator to determine the approximate number of linear feet you can seal based on the amount you have on hand or use it to estimate the number of tubes you will need to

RTV Silicone Sealant FAQs |RTV Silicone sealant at best price| Mumbai IN

Types of adhesives for windshields

Types of adhesives for windshields Windshield replacement

Windshield replacement

Anagha Engineers has formulated a MS Sealant for such applications.Not only that it is simple to use but also that it does not require trained labour. Just apply a uniform bead of the adhesive onto the areas which need to bond. Assemble it against the

Anagha Engineers has formulated a MS Sealant for such applications.Not only that it is simple to use but also that it does not require trained labour. Just apply a uniform bead of the adhesive onto the areas which need to bond. Assemble it against the

It is a food grade

It is a food grade  Silirub B&K is an anti-fungal

Silirub B&K is an anti-fungal  sealant is Low odor, ageing and weathering resistant, bonds well to a wide variety of substrates without the need for special pretreatments. It is suitable for interior and exterior elastic sealing and bonding applications on substrates such as timber, glass, metals, metal primers, ceramic materials and

sealant is Low odor, ageing and weathering resistant, bonds well to a wide variety of substrates without the need for special pretreatments. It is suitable for interior and exterior elastic sealing and bonding applications on substrates such as timber, glass, metals, metal primers, ceramic materials and  high-performance sealant and ideal to use in HVAC applications. Supex Duct Acrylic Sealant provides excellent strength, bonding and forms a strong seal against

high-performance sealant and ideal to use in HVAC applications. Supex Duct Acrylic Sealant provides excellent strength, bonding and forms a strong seal against  based elastomeric sealant / adhesive that was

based elastomeric sealant / adhesive that was systems that make a home comfortable create penetrations (openings) that can create drafts, making living spaces uncomfortable. These penetrations not only allow

systems that make a home comfortable create penetrations (openings) that can create drafts, making living spaces uncomfortable. These penetrations not only allow