Adhesives & Sealants for Bus Body

The bus manufacturing industry is upgrading from mechanical fasteners and replacing them by adhesives and sealants . The shift towards adhesives and sealants in bus assembly processes is encouraged by the need for increased sustainability, use of composite materials, aerodynamic designs and safety regulations. .

Here you will find everything you need to know about adhesives and sealants used in different stages of bus manufacturing.

Bus Body adhesives sealants makes stronger, safer and lighter buses

Adhesives and sealants for buses are designed to meet the requirements of making the process and products stronger, safer, faster and lighter.

- Stronger: adhesives and sealants increase the durability of buses as they prevent corrosion unlike mechanical fasteners which are prone to cause galvanic corrosion.

- Safer:some adhesives and sealants are designed to damp impact, which makes them improve the buses´ crash test performance. Also fire retardant adhesives improve safety on board.

- Lighter: the use of adhesives and sealants instead of mechanical fasteners can lead to substiantial weight reduction. Adhesives make it possible to bond indifferent materials together without needing to worry about damaging either of the materials.

- Faster: not only allow adhesives and sealants for more aerodynamic designs, but they are also faster to process, which reduces the production time of buses.

Advantages of using Bus Body adhesives & sealants

- Smooth surface appearance and less rework

- Bonding dissimilar materials increasing design freedom

- Reduced risk of corrosion

- Increased comfort due to dampening sound and vibration

- Longevity and durability

- Reduced weight due to the elimination of mechanical fasteners

- Dampening sound and vibration

- Improved body stability and reduced fuel consumption due to lighter weight

- Increased impact safety in the event of a crash

- Resistance against extreme temperature conditions

- Design freedom due to thermoplastics

- Environmentally friendly bonding solutions

- Fast production process

- Cost reduction

- Improved aerodynamics

- Roof sealing, roof bottom sealing for mica bonding

- Roof gap sealing

- Side panel

- Floor bonding with plywood

- Dashboard bonding

- Plywood bonding in Driver cabin

- Rear FRP& FRP bumper

- front FRP

- Battery box sealing

- FRP stair sealing

- Vinyl bonding on to floor

- skirt panel bonding

- Side glass window frame pillar bonding

- front wind shield & rear wind shield

- Gap between window frames

- sealing beading on roof side

- ABS to frame

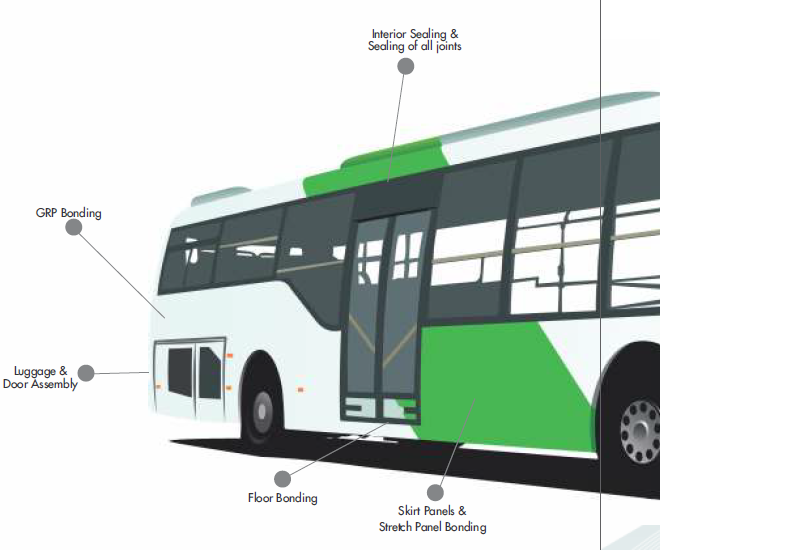

Applications of adhesive and sealant are continuously increasing. It is not only about making windows watertight but also keeping the body structure together. The adhesive and sealant applications not only focus on the frame, interior and exterior of the buses, but also contribute to the mechanisms under the hood including engine components and batteries. Below you will find the more specific applications of adhesives and sealants for buses.

Body structures

During the assembly of bus body structures, several adhesives and sealants are used in order to prevent corrosion, water ingress and standing water. They also contribute to comfort during long bus rides.

Adhesive & sealant solutions

There are easy to process, one component sealants such as MS polymers The growing demand for MS polymers is based on the need for environmentally friendly products.

Bus roof sealing and bonding

The roof is one of the most important parts of a bus, and the design still is one of the greatest challenges for bus manufacturers. Similar systems are also used to glue antennas and receivers on bus roofs.

Adhesives & sealants solutions

Bus roof sealing and bonding require flexible solutions which are not affected by whatever the environment might throw at the roof. The bus roof sealant and adhesive systems are often polyurethane based or hybrid systems. They exist as one and 2 component systems which allow for fast curing, speeding up the production process.

Bus floor sealing, side panels, luggage doors and hatches

Bus operators expect outstanding durability from their vehicle regardless the driving conditions. Therefore, the bus must be safe in possible crash situation and it should not degrade due to harsh climatic conditions.

Adhesive and sealant solutions

For sealing floors, side panels, luggage doors and hatches MS polymers are a common choice . The bonding of these applications is often realized with elastic polyurethane adhesives which cure fast and exist as one and two component systems. Also MMA adhesives are common for bonding interior panels.

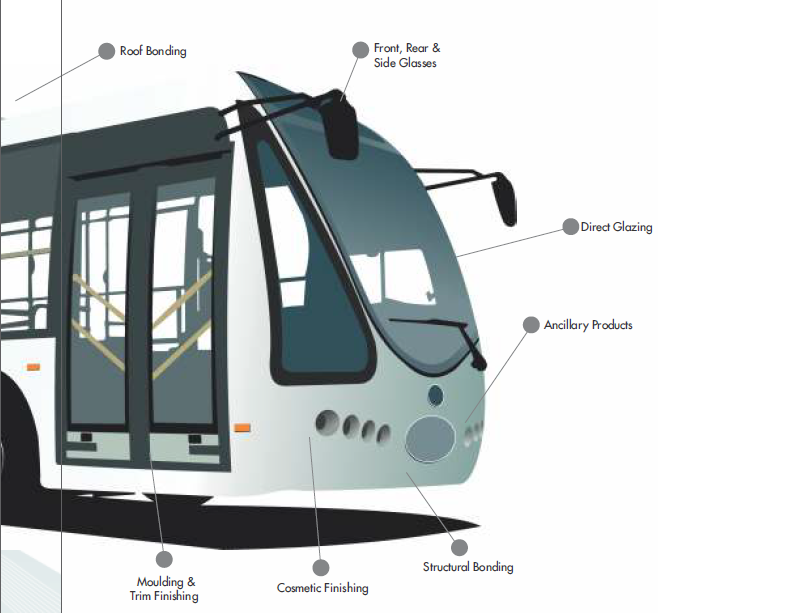

Front and rear masks

The front and rear masks contribute to the aerodynamic design of buses. The use of adhesives and sealants instead of mechanical fasteners allows for more aerodynamic shapes and so contributes to reduced fuel consumption.

Adhesive and sealant solutions

Adhesives and sealants for front and rear masks of buses are usually thermoplastics which can be shaped when not completely cured. The solutions include polyurethane and hybrid systems which cure fast allowing for shorter processing times. The adhesive and sealant systems are usually one component solutions, which makes the processing less laborious.

Interior trim

The development of interior design of buses has lead to the use of ever-growing mix of plastics and fabrics which require durable and environmentally friendly bonding solutions. The adhesives for bus interior trim improve appearance and contribute to comfort.

Adhesive and sealant solutions

The most used adhesive for bus interiors is hot melt which appears in a solid phase in room temperature, and softens when heated. These adhesives allow for extremely fast processing. Hot melt adhesives are also used for example for furniture upholstery.

Bus direct glazing adhesive and sealant solutions

They are used for sealing and bonding direct glazing application as they provide fast curing times and high initial strength as well as contribute to aerodynamic design and stability of the vehicle. As the glazing of buses involves large and heavy surfaces, the adhesive must be chosen carefully opting for the highest quality. In some cases the direct glazing adhesive must be sealed using an appropriate sealant system. Gain more information on the best glazing adhesives and sealants!

Adhesive and sealant solutions

The products included MS polymers, silicone sealants and polyurethane based adhesives.

Adhesive & Sealant applications

Pu adhesive sealant for auto glass/car windshield/bus body

Sheet metal, panel, FRP, Composites bonding

Boss PU 25 / Supex PU 25, Soudaflex 611, Soudaflex 621 – These PU Sealants are particularly designed for sealing application in areas including Bus & Coach, Truck, Earth moving Equipments, Tractor, Forklift, OEM, Repair Auto After Markets also various other commercial and industrial vehicles.

Further, it bonds a variety of material including FRP, GRP, timber, plywood, metals, particularly aluminium (including

anodized components), sheet steel (including phosphated, chromated and zinc-plated components), coated metals and paint coatings (two-part systems), ceramic materials as well as plastics.

Windscreen bonding, metal to glass Bonding

Supex PU 75 is a one-component, medium-modulus polyurethane sealant that cures on exposure to atmospheric humidity. Specially formulated for windscreen bonding applications. Suitable for glass bonding in trains and coachwork.It possesses excellent adhesion to all typical construction materials such as cement based materials, brick, ceramic, glass, wood, galvanized and painted sheet iron and various plastics.

BOSS PU 50 is a fast-curing one-component moisture curing polyurethane adhesive sealant that turns into a flexible, durable and resistant elastomeric seam and has a very good adhesion to most industrial materials. It has high elasticity and excellent tear, vibration and weathering resistance. Easy to apply, it adheres without primer to the most common substrates, such as glass, anodized aluminum, lacquered metal, wood, FRP, and concrete.

Kindly post your questions/ queries in the comment section or contact me at:

Bibhas Agarwal

anaghaengineers.in@gmail.com

Whatsapp: 91 9833892782

Call : 91 9699892782

www.anaghaengineers.in